About 60 cell and 72 cell (and 144 cell) panels

The vast majority of solar panels available on the market today fall into a class named for how many cells are typically wired in one series string on the panel. The industry started to do this many years ago to make it easier for vendors of charging equipment to more closely match the power output from the panels to the voltages necessary to charge batteries and to sell directly back to the grid via on site inverters or micro-inverters.

We will discuss some of the details of those types of panels here, and if you want to go into more depth you should look at our Solar Calculations and Tutorial page.

We consider the cost/power tradeoff of all of these types of panels, coupled with power requirements of your system when helping you decide what will be best for you, whether it is water pumping, off grid power, or a space constraint on a roof.

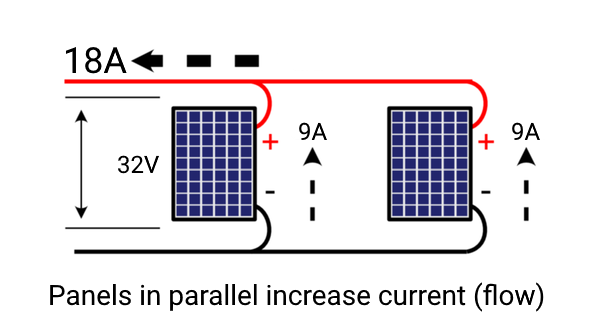

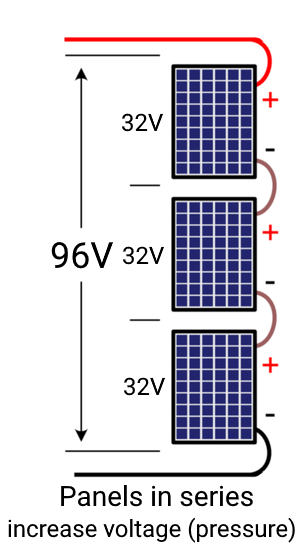

Voltage and Current

Just like with the explanations of panel voltages on the Solar Calculations and Tutorial page, cell voltages add when in series and cell currents add when in parallel.

What are we missing?

Let us know what other topics or advanced topics you would like covered